Calcium sulfate raised floors are widely used in data centers, offices, laboratories, and commercial buildings. The two most common types are Antistatic Calcium Sulfate Raised Floor and Steel Encapsulated (Six-Side Steel) Calcium Sulfate Floor. Here is a simple comparison.

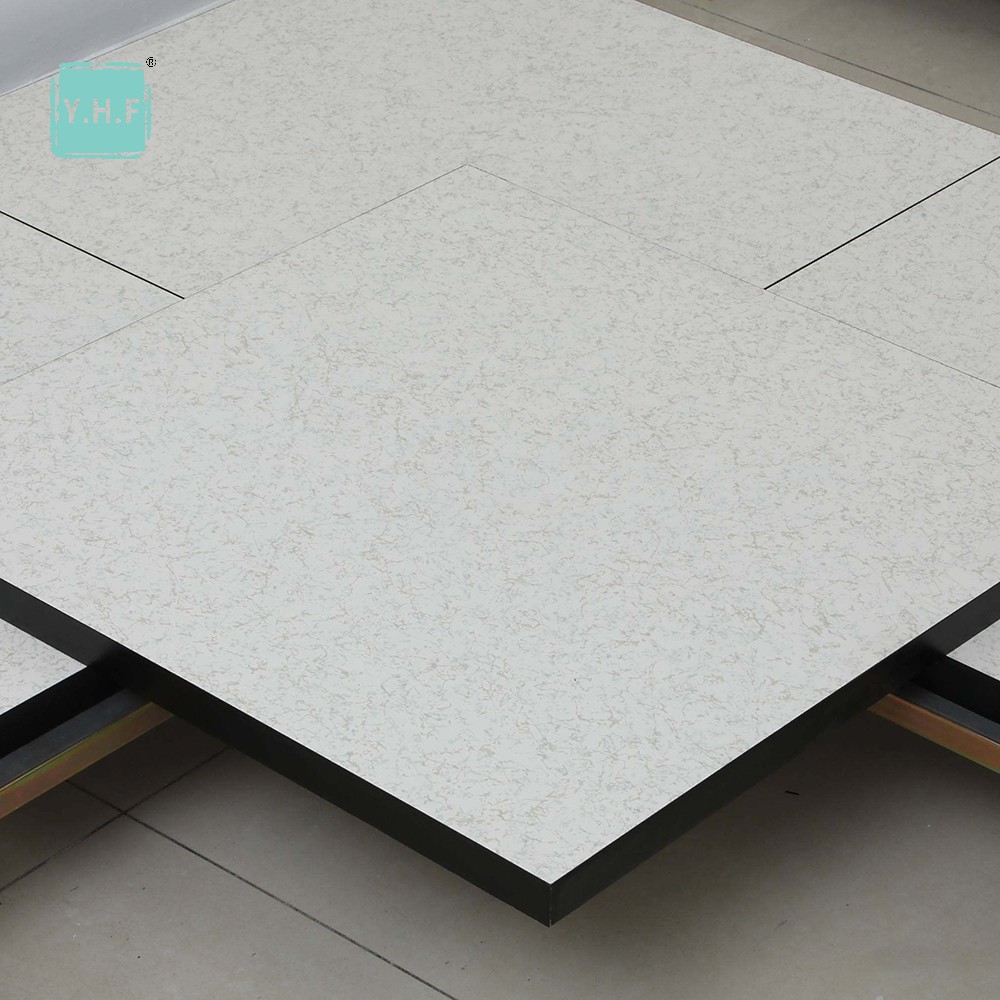

Antistatic Calcium Sulfate Raised Floor

This floor uses a high-density calcium sulfate core combined with antistatic surface materials such as HPL, PVC, or ceramic.

Features:

Provides reliable antistatic performance

Flexible cable management with a raised structure

Eco-friendly core with good stability

Multiple surface options

Best for: Data centers, server rooms, electronics workshops, and laboratories.

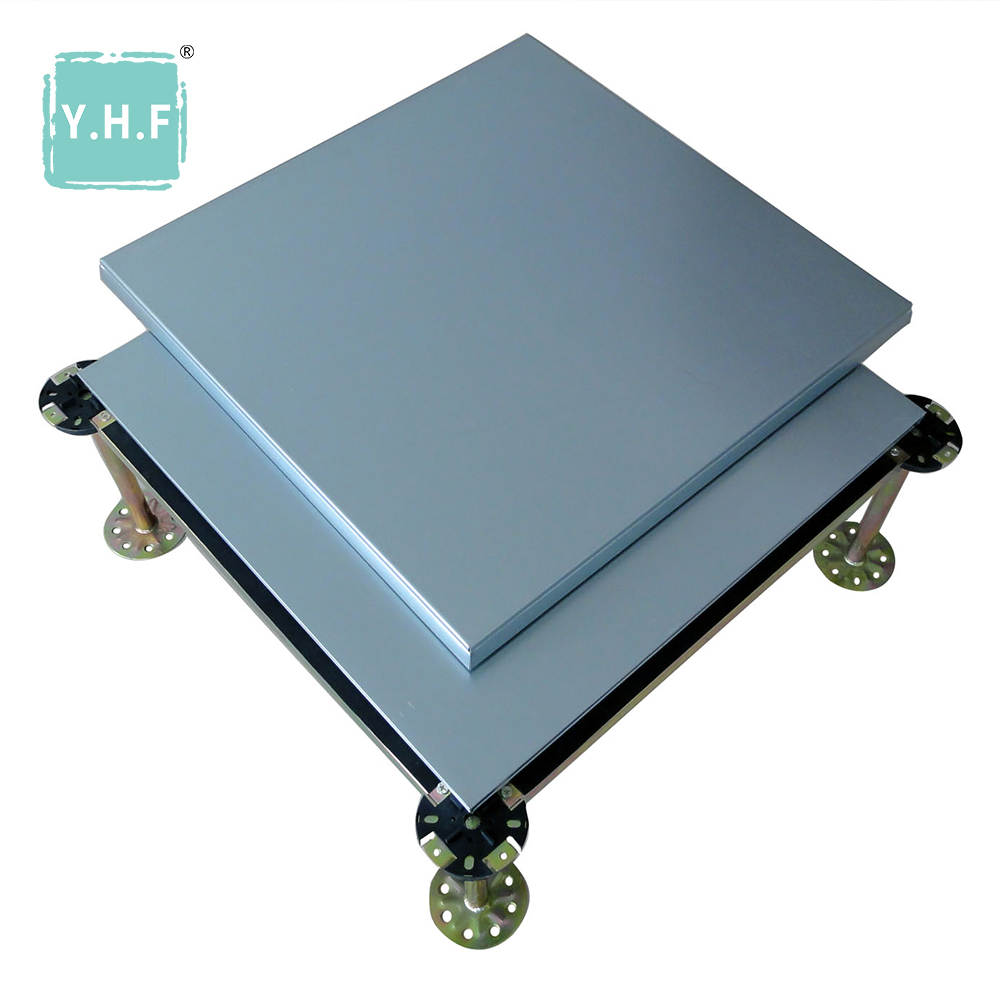

Steel Encapsulated (Six-Side Steel) Calcium Sulfate Floor

This type fully wraps the calcium sulfate core with galvanized steel on all six sides, offering enhanced protection.

Features:

Excellent moisture resistance and durability

Higher load-bearing performance

Stable in heavy-traffic or humid environments

Compatible with antistatic surfaces if needed

Best for: Office buildings, control rooms, commercial facilities, heavy-load areas.

Key Differences

| Item | Antistatic Calcium Sulfate Raised Floor | Steel Encapsulated Calcium Sulfate Raised Floor |

| Structure | Core + surface | Fully steel-wrapped |

| Antistatic | Strong | Optional (depends on surface) |

| Load Capacity | Medium–High | High–Very High |

| Moisture Resistance | Good | Excellent |

| Cost | More economical | Higher |

Y.H.F FLOORS Solutions

Y.H.F FLOORS provides both types of calcium sulfate raised floors, pedestal systems, and surface materials (HPL / PVC / ESD/ Ceramic).

We support global data centers, office projects, and commercial spaces with stable and high-performance flooring solutions.

Contact us anytime.