- Core physical performance review

- Conductivity Test (Key Items)

- Appearance and defect control

On November 27, I went to the factory to see the upcoming shipment ESD Vinyl Tiles(YHE-1802 / YHE-1816). Final inspection before leaving the factory was carried out. For functional products such as anti-static flooring, laboratory data is theoretical support, and on-site review is the last line of defense for delivery safety.

The following is a summary of the key verification points of this inspection:

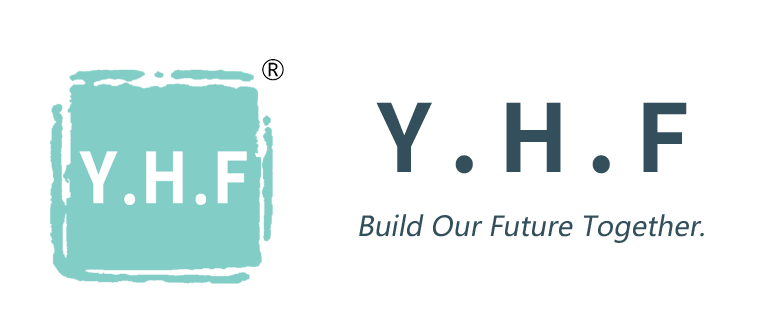

Core physical performance review

Random sampling measurements were carried out on site. The specifications of the two gray floor tiles are unified as follows 600×600mm, the thickness of the center and edge is controlled 2mm (error ±0.2mm) Within the scope, the flatness meets the procurement standards and can meet the strict requirements of precision electronic workshops for ground flatness.

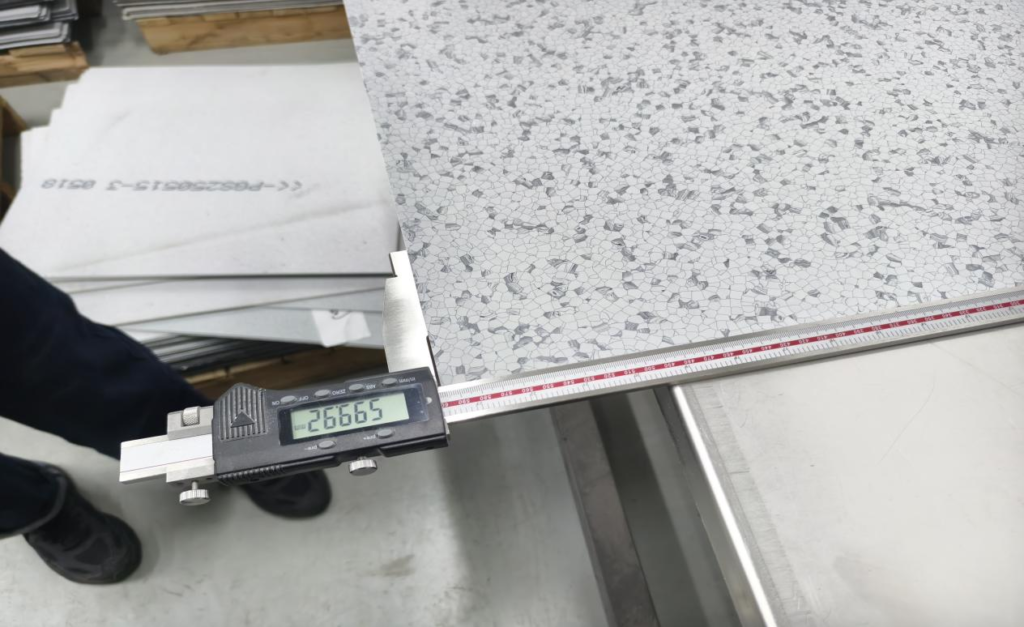

Conductivity Test (Key Items)

According to the datasheet, this batch belongs to: Conductive Level. Multi-point testing with professional instruments is used on site, and the resistance reading is stable

1.0×104−1.0×106Ω1.0×104−1.0×106Ω

Interval. This data is consistent with the factory laboratory report, confirming that it has stable electrostatic dissipation and conductivity in compliance with international standards such as ANSI/ESD S20.20.

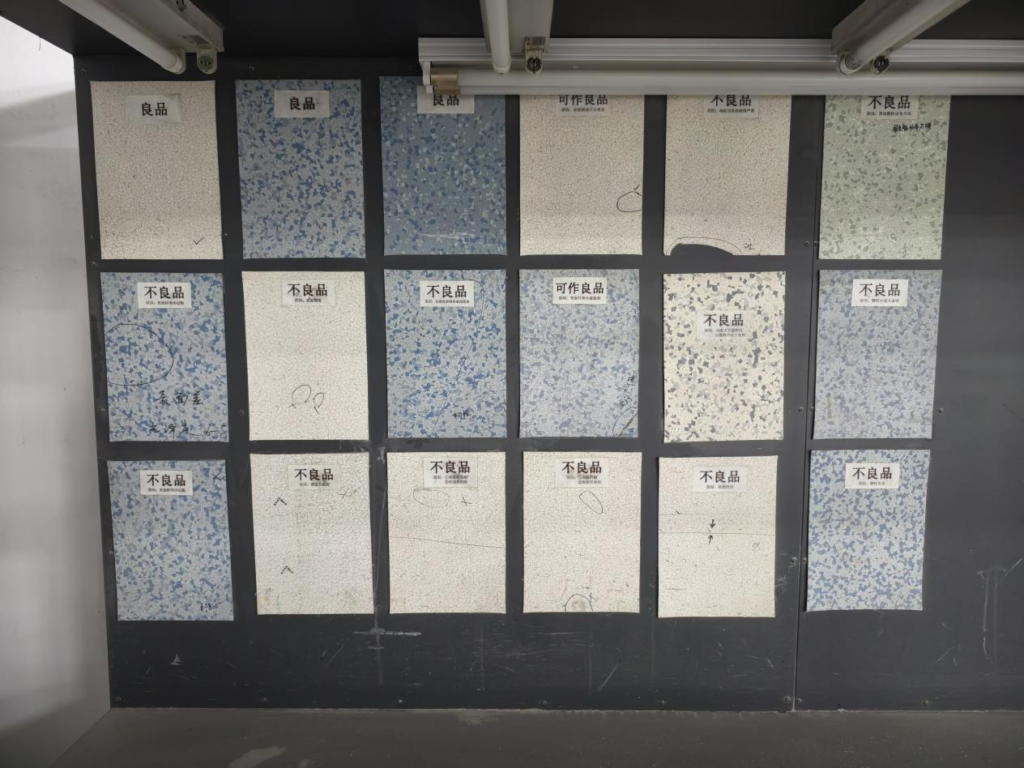

Appearance and defect control

By comparing it with factory “defective product samples” (e.g., edge burrs, surface stains), we recalibrated the acceptance criteria. After investigation, the surface finish and edge cutting quality of the bulk finished products reached excellent grades, eliminating potential installation hazards.

summary

This inspection confirmed that YHE-1802 and YHE-1816 meet the delivery requirements in terms of physical specifications, conductivity and packaging details. We will continue to implement a rigorous quality control process to ensure that every piece of flooring delivered to our customers stands up to the test of the on-site environment.