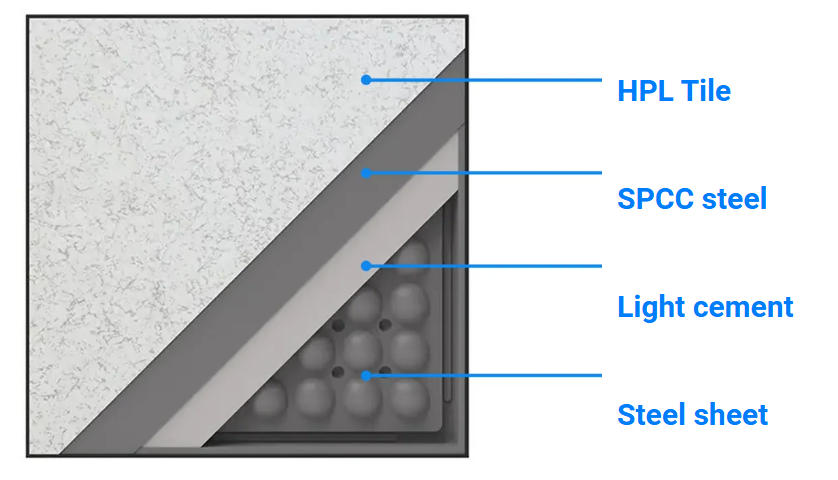

Y.H.F HPL Raised Floor panel is crafted from high-quality deep stretch coil steel and SPCC steel sheets. The sheets are carefully punched, spot-welded, phosphorated, and coated with epoxy powder to ensure long-lasting durability. The interior is filled with foamed cement, which, after curing, forms a stable support structure. The top steel sheet is bonded with anti-wear and antistatic HPL, providing both resilience and a professional finish.

Typical Structure

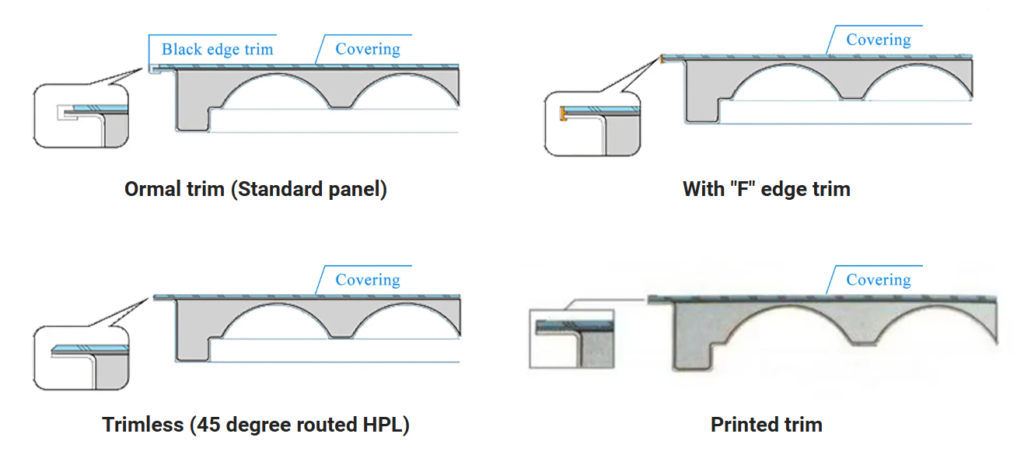

Edge Trim Type

Technical Specifications

| System Name | HPL Panel Raised Floor |

|---|---|

| Finished Floor Height | 100–1000 mm |

| Panel Size | 600 × 600 × 35 mm |

| Edge Trim Type | Normal trim, Trimless, “F” edge trim, Printed trim |

| Finish Covering | 1.0–2.0 mm Anti-static Laminate HPL |

| Installation | With stringer system |

| System Resistance | Conductive: <1×10⁶ Ω; Dissipative: 1×10⁶–1×10¹⁰ Ω |

| Fire Performance | Class A |

Key Features

All-Steel Construction: Superior strength, durability, and long-term performance.

Excellent Fire Resistance: Meets Class A flame spread and smoke development ratings for enhanced safety.

High Dimensional Accuracy: Ensures stable panel alignment and consistent floor performance.

Optimized for Technical Environments: Perfect for computer rooms, data centers, and communication hubs.

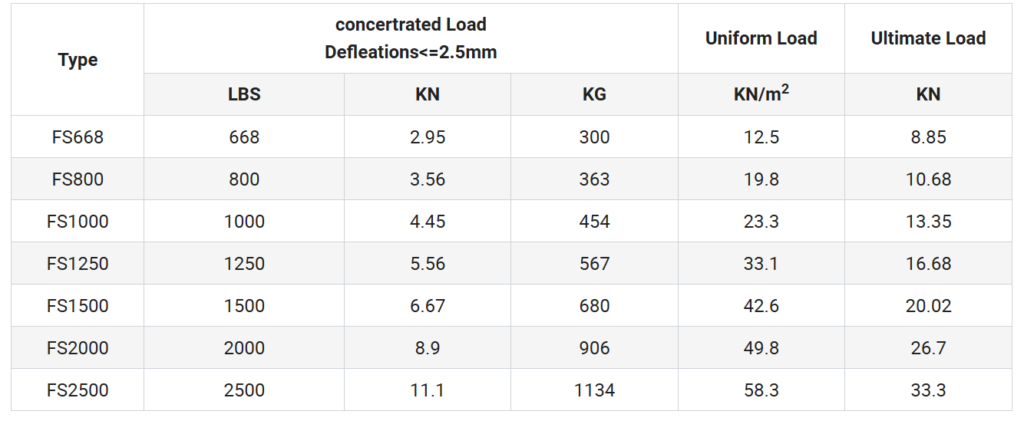

Superior Load Performance: Outstanding rolling and ultimate load capacity for heavy equipment.

Lightweight Cement Core: Solid and quiet underfoot experience while reducing overall floor weight.

Protective Finish: Black or grey epoxy coating provides long-lasting corrosion resistance.

Easy Installation: Modular design allows quick setup and efficient management of office layouts, wiring, and data cabling.

Application Areas